Strip Cutting

At HookandLoop.com, we offer our hook and loop strip cutting services with a straight cut free of charge to our customers. We can run widths from 3/8" to 4" through our strip cutter (please note: there is a variance on all cut orders of 1/16" +/-) so the rolls can come in slightly over or slightly under piece count. We do not charge you to cut your hook or loop to any length over one inch. Rolls cut under 1" are $5.00 per roll additional. We can cut each roll separately or cut and mate the rolls to any length you need.

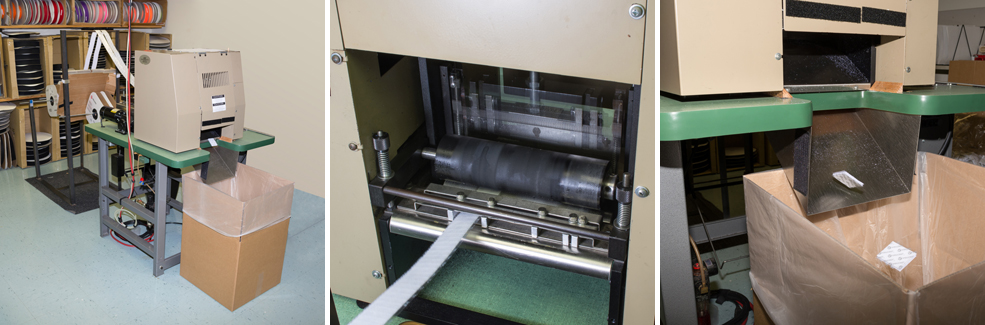

Hook and loop strip cutting is simply the process of cutting material to a specified length. At HookandLoop.com, that means cutting certain rolls of hook and loop to a certain length, repeatedly. If you have a need for 10,000 1” x 6” pieces of Peel & Stick Hook, we’ll cut that for you for free. If you need 500 3/4” x 2” pieces of Sew-On Loop, we’ll cut that for you for free. We use fabric strip cutting machines that require the input of length and quantity. The machine then feeds the material through, using gears to calculate length, and then cuts the material with a scissor-like blade. The VELCRO® Brand and DuraGrip® strip cutting process cuts the rolls to a straight cut. This is our Free Service.

We use two straight cutting machines, meaning they cut straight across the material, creating a squared off tip. These are mostly used for cutting Peel & Stick hook or loop for a wide variety of customer uses, from hospitals and doctors’ offices using them to adhere biohazard signs, to cleaning services using them to adhere bathroom mats and air fresheners.

We also use our fabric strip cutting machines to cut and mate the hook and loop material together, further reducing customer labor costs. Our straight strip cutter machines also cut the loop portions of our hook and loop straps that we manufacture. These pieces are straight cut so we can weld the loop portion to the hook portion. For strap manufacturing, these straight cutting machines work in conjunction with our tip cutting machine. The tip cutting machine uses a die to cut a round tip (a half circle) or a bullet nose tip (a rounded triangular cut) on one end. These tip shapes are generally used to improve function and design.

By clicking “Accept All”, you agree to the storing of cookies and similar technologies on your device to enhance your browsing experience, analyze traffic, and personalize content.